Synthetic leather industry

Color paste products are used for pigment coloring in the production of various synthetic leathers, such as shoe, clothing, and bag leathers, automotive interior leathers, and sofa leathers. They provide uniform color and good adhesion, ensuring that the product is beautiful and durable.

Silicone auxiliaries are used to improve the wear resistance of synthetic leather, giving PU leather excellent aging resistance, as well as a soft and smooth feel. They also improve the surface leveling of synthetic leather, making the coating more uniform and reducing surface defects such as pinholes and poor leveling.

Coatings industry

Color paste products provide color to the coatings industry, improve pigment dispersibility, enhance coating performance, and facilitate color matching, meeting the diverse color needs of the coatings industry and improving its overall performance.

The silicone additive product series can impart various haptic sensations to the paint film surface, improve wear and scratch resistance, reduce paint film surface tension, improve its leveling properties, and have excellent defoaming and anti-foaming effects, thereby optimizing the application performance of coatings and the quality of the coating.

Textile coating industry

Color paste products are used in the production of coated fabrics, providing uniform color and good adhesion to meet the dual needs of color and performance for textiles, outdoor products, furniture fabrics, and advertising fabrics.

The silicone additive product series can reduce the surface tension of the coating, improve its leveling and uniformity, reduce defects such as pinholes and shrinkage, enhance the fabric feel and functionality, and meet the market demand for high-performance textiles.

Automotive industry

Color paste products are widely used in automotive interior leather and exterior paint color matching, providing high-gloss, weather-resistant color solutions to meet the stringent quality and aesthetic requirements of automotive manufacturing.

The silicone additive product series can improve the surface tension of automotive paint films, reduce defects such as pinholes and orange peel, and give the interior surface a soft, delicate, and skin-friendly feel, ensuring the uniformity and stability of the coating.

Manufacturing industry

In industrial manufacturing, color pastes are used for coloring various products such as coatings, plastics, and inks. They are widely applied in industries such as automobiles, home appliances, building materials, and packaging, giving products an aesthetic appearance and good visual effects.

In industrial manufacturing, silicone additives optimize production processes, enhance product quality and performance, and improve product market competitiveness by improving material surface properties, dispersibility, lubricity, and defoaming effects.

Printing and manufacturing industry

Color paste products are used in the coating process of optical films, protective films, decorative films, etc., providing uniform color and good adhesion, giving products rich colors, ensuring uniform coating color and high transparency, and improving product quality.

In the printing of work in progress, organosilicon additives improve the leveling, dispersion, and anti-blocking properties of the ink, reduce defects in the printing process, improve printing efficiency and finished product quality, and meet the needs of different printing processes.

Sporting goods industry

Color paste products provide vibrant, durable, and eco-friendly color solutions for the sporting goods industry. They are widely used in products such as plastic running tracks, basketballs, PVC flooring, and yoga mats, significantly enhancing their appearance and market competitiveness.

Silicone additives optimize abrasion resistance, feel, and application performance, providing the sporting goods industry with efficient and reliable performance support. This helps enhance the durability and user experience of products such as plastic running tracks, basketballs, PVC flooring, and yoga mats.

Daily Chemical Industry

In the daily chemical industry, color pastes are used to color the appearance of cosmetic bottles, providing them with a rich array of colors to enhance visual appeal and meet consumer demand for personalized aesthetics.

Silicone additives are widely used in skin care products, hair care products, and cosmetics to provide products with good lubricity, smoothness, and stability, enhancing user experience and product performance.

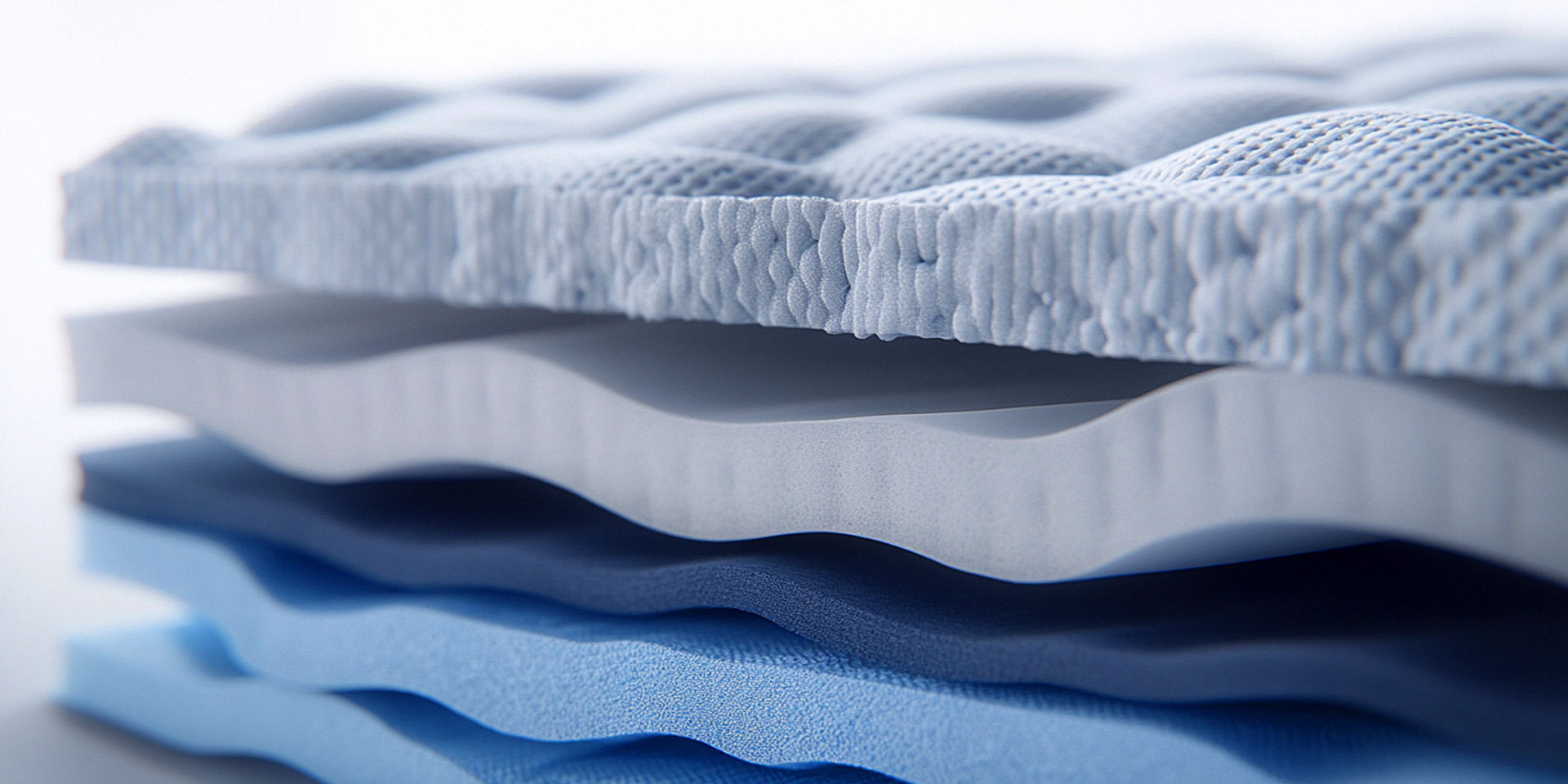

Sponge products

Color paste products provide uniform color and good adhesion, giving products rich color and stable performance.

Auxiliary products are used in the production of sponges. Dispersants and defoamers ensure uniform foaming and stable molding of sponges, improving product quality and performance.